- You cannot add that amount of "GYTS Standard Loose Tube Steel Tape Armored Cable" to the cart because there is not enough stock (0 remaining).

GYDTS Loose Sheathed Stranded Light Armored Fiber Optic Cable

$2.25

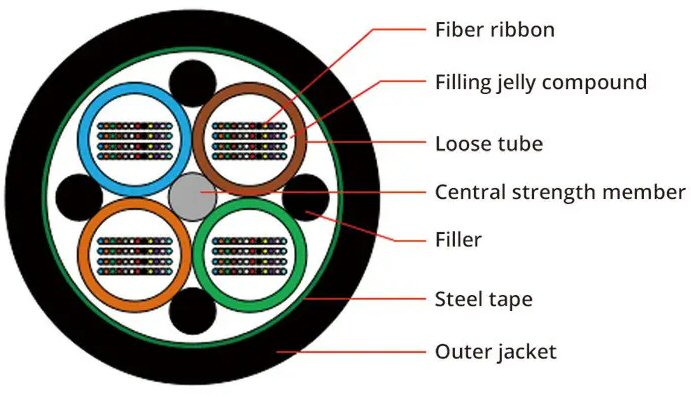

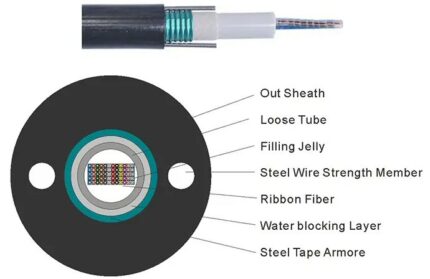

The structure of GYDTS optical cable is to put 4, 6, 8, 12 core optical fiber ribbon into a loose tube made of high modulus material, and the loose tube is filled with waterproof compound. The center of the cable core is a metal reinforced core. For some optical fiber cables, a layer of polyethylene (PE) needs to be extruded outside the metal reinforced core. The loose tube and the filler rope are twisted around the central reinforcing core to form a compact and round cable core, and the gaps in the cable core are filled with water blocking fillers. The double-sided plastic-coated steel tape (PSP) is longitudinally wrapped and extruded into a polyethylene sheath to form a cable.

Product Manual:GYDTS (Opticalfiber ribbon, Loose tube stranding, Metal strength member, Flooding jellycompound, Steel-polyethylene adhesive sheath)

Product Standards:

GYDTS optical cable complies with YD / T 981.3 and IEC 60794-1 standards.

0 in stock

Product Description:

GYDTS (Opticalfiber ribbon, Loose tube stranding, Metal strength member, Flooding jellycompound, Steel-polyethylene adhesive sheath)

Standards:

YD/T 981.3-2009 Optical fiber ribbon cable foraccess network

Features

• Has good mechanical properties and temperature characteristics

• The loose tube material itself has good hydrolysis resistance and high strength

• The tube is filled with special grease to protect the optical fiber critically

• Specially designed compact optical cable structure effectively prevents the casing from retracting

• Good pressure resistance and flexibility

• PE jacket has good resistance to ultraviolet radiation

• Adopt 4, 6, 8, 12 core optical fiber ribbon, flexible application

• Use the following measures to ensure the waterproof performance of the optical cable:

-Single steel wire center reinforced core

-Loose casing filled with special waterproof compound

-Complete cable filling

-Double-sided plastic coated steel strip (PSP) improves the moisture resistance of optical cable

| Fiber Count | Structure | Diameter(mm) | Weight (kg/km) | Tensile(N)Long Short term term | Crush(N)Long Short term term | Bending Radius(mm)Static Dynamic | |||

| 48-144 | 1+4 | 17. 2 | 276 | 600 | 1500 | 300 | 1000 | 10D | 20D |

| 156-192 | 1+4 | 17. 2 | 283 | 600 | 1500 | 300 | 1000 | 10D | 20D |

| 194-216 | 1+4 | 18. 7 | 334 | 600 | 1500 | 300 | 1000 | 10D | 20D |

| 218-288 | 1+4 | 18. 7 | 337 | 600 | 1500 | 300 | 1000 | 10D | 20D |

| 290-432 | 1+4 | 20. 6 | 400 | 600 | 1500 | 300 | 1000 | 10D | 20D |

| 434-576 | 1+4 | 22.8 | 478 | 600 | 1500 | 300 | 1000 | 10D | 20D |

2.The relevant technical Parameters canbe adjusted according to the customer’s demands;

3.The block water way can be adjustedaccording to the customer’s demands;

4.The design flame resistance,anti-rodent, termite resistant cable according to the customer’s demands.

Related products

- Small size, Low cost.

- Up to 24 fibers.

- Uni-tube gel-filled construction for superior fiber protection.

- Two parallel FRP wire and overall glass yarn to enhance tensile resistant.

- And protect cable from mechanical damage.

- Designed for use with inexpensive attachment hardware.

- Self-supported no messenger needed.