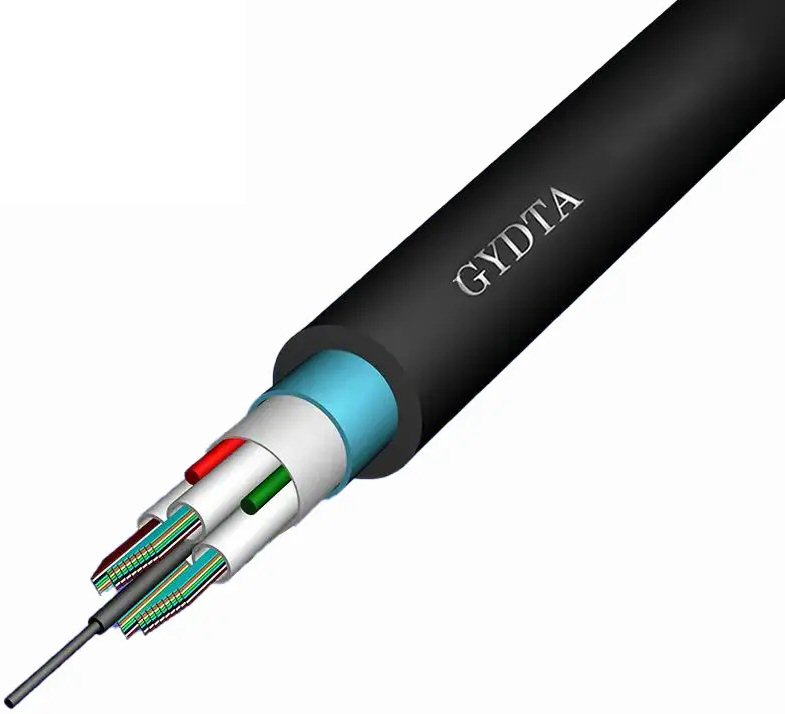

GYDTA Fiber Optic Ribbon Cable(SM/MM 48-576 Fibers)

$1.25

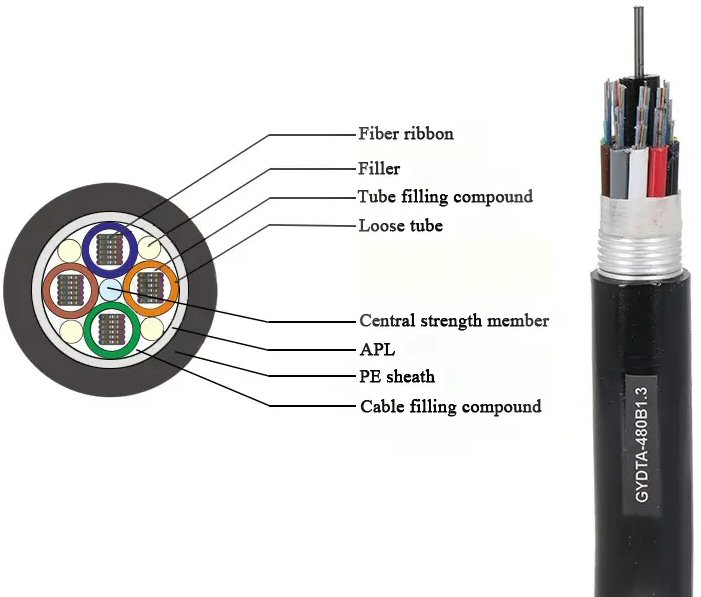

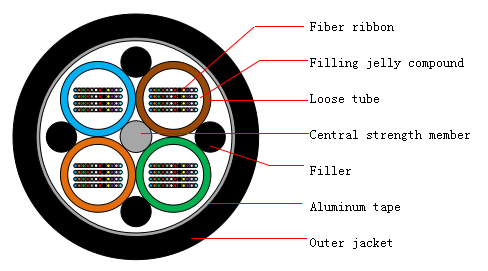

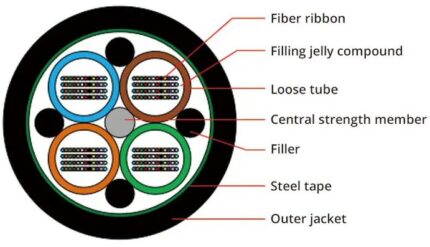

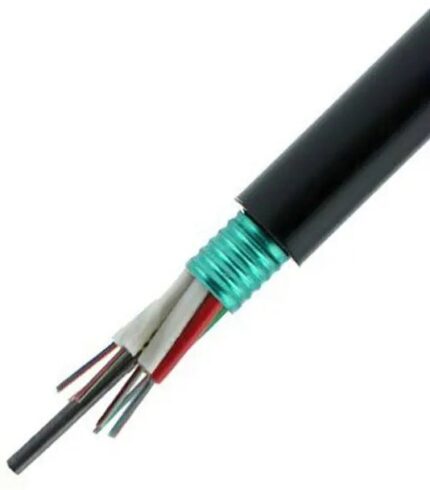

The fiber ribbons are positioned in the loose tube. The loose tubes are made of high modulus plastics (PBT) and filled with a water resistant filling gel. Loose tubes and fillers are stranded around the metallic central strength member, cable core is filled with cable filling compound. The corrugated aluminum tape is longitudinally applied over the cable core, and combined with a durable polyethylene (PE) sheath.

Product Manual:GYDTA (Opticalfiber ribbon, Loose tube stranding, Metal strength member, Flooding jellycompound, Aluminum-polyethylene adhesive sheath)

Application:

Duct installation

Access network

CATV network

Standards: YD/T 981.3-2009 Optical fiber ribbon cable foraccess network

0 in stock

Structure:

Central strength member: FRP available

Loose tube: PP or other materials available

Water blocking materials for cable core: water blocking tape available

Outer sheath: PE, steel tape armor, anti-termite or flame retardant materials available

Features:

High fiber density

All section water blocking

Excellent transmission, mechanical and environmental performance

Anti-ultraviolet radiation

Easy identification, easy branching, easy maintenance

Lifespan over 30 years

Installation performance:

Min. bend radius: installation 20D, operation 10D

Temperature range: storage -40~+70℃, installation -30~+70℃, operation -40~+70℃

Technical Parameters(Typical Value):

| Fiber Count | Structure | Diameter(mm) | Weight (kg/km) | Tensile(N)Long Short term term | Crush(N)Long Short term term | Bending Radius(mm)Static Dynamic | |||

| 48-144 | 1+4 | 17. 2 | 250 | 600 | 1500 | 300 | 1000 | 10D | 20D |

| 156-192 | 1+4 | 17. 2 | 256 | 600 | 1500 | 300 | 1000 | 10D | 20D |

| 204-216 | 1+4 | 18. 7 | 305 | 600 | 1500 | 300 | 1000 | 10D | 20D |

| 228-288 | 1+4 | 18. 7 | 308 | 600 | 1500 | 300 | 1000 | 10D | 20D |

| 300-432 | 1+4 | 20. 6 | 366 | 600 | 1500 | 300 | 1000 | 10D | 20D |

| 444-576 | 1+4 | 22.8 | 442 | 600 | 1500 | 300 | 1000 | 10D | 20D |

Note:

1.D refers to the cable diameter;

2.The relevant technical Parameters canbe adjusted according to the customer’s demands;

3.The block water way can be adjustedaccording to the customer’s demands;

4.The design flame resistance,anti-rodent, termite resistant cable according to the customer’s demands.

Related products

- Small size, Low cost.

- Up to 24 fibers.

- Uni-tube gel-filled construction for superior fiber protection.

- Two parallel FRP wire and overall glass yarn to enhance tensile resistant.

- And protect cable from mechanical damage.

- Designed for use with inexpensive attachment hardware.

- Self-supported no messenger needed.