GYDTS Loose Sheathed Stranded Light Armored Fiber Optic Cable

$2.25

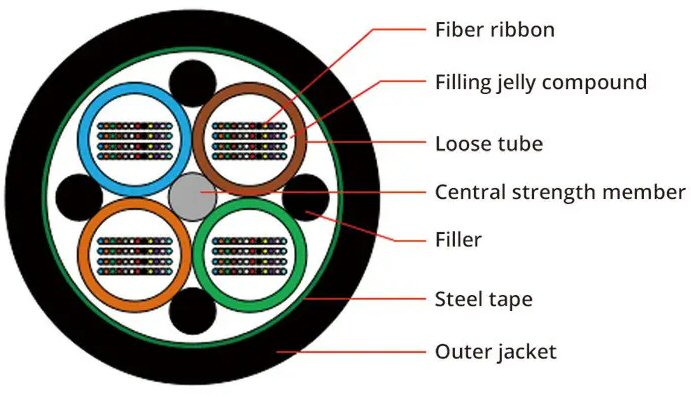

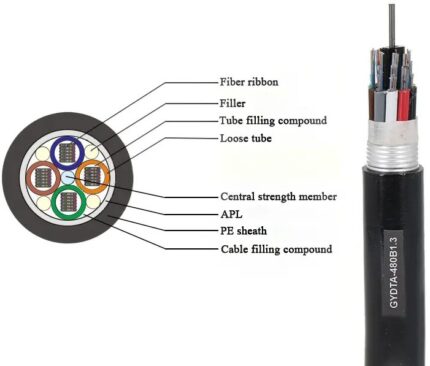

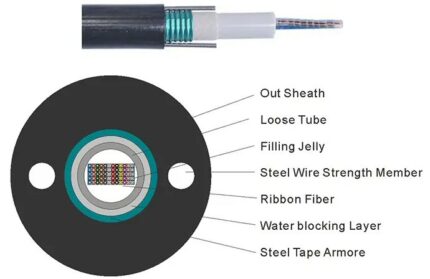

The structure of GYDTS optical cable is to put 4, 6, 8, 12 core optical fiber ribbon into a loose tube made of high modulus material, and the loose tube is filled with waterproof compound. The center of the cable core is a metal reinforced core. For some optical fiber cables, a layer of polyethylene (PE) needs to be extruded outside the metal reinforced core. The loose tube and the filler rope are twisted around the central reinforcing core to form a compact and round cable core, and the gaps in the cable core are filled with water blocking fillers. The double-sided plastic-coated steel tape (PSP) is longitudinally wrapped and extruded into a polyethylene sheath to form a cable.

Product Manual:GYDTS (Opticalfiber ribbon, Loose tube stranding, Metal strength member, Flooding jellycompound, Steel-polyethylene adhesive sheath)

Product Standards:

GYDTS optical cable complies with YD / T 981.3 and IEC 60794-1 standards.

0 in stock

Product Description:

GYDTS (Opticalfiber ribbon, Loose tube stranding, Metal strength member, Flooding jellycompound, Steel-polyethylene adhesive sheath)

Standards:

YD/T 981.3-2009 Optical fiber ribbon cable foraccess network

Features

• Has good mechanical properties and temperature characteristics

• The loose tube material itself has good hydrolysis resistance and high strength

• The tube is filled with special grease to protect the optical fiber critically

• Specially designed compact optical cable structure effectively prevents the casing from retracting

• Good pressure resistance and flexibility

• PE jacket has good resistance to ultraviolet radiation

• Adopt 4, 6, 8, 12 core optical fiber ribbon, flexible application

• Use the following measures to ensure the waterproof performance of the optical cable:

-Single steel wire center reinforced core

-Loose casing filled with special waterproof compound

-Complete cable filling

-Double-sided plastic coated steel strip (PSP) improves the moisture resistance of optical cable

| Fiber Count | Structure | Diameter(mm) | Weight (kg/km) | Tensile(N)Long Short term term | Crush(N)Long Short term term | Bending Radius(mm)Static Dynamic | |||

| 48-144 | 1+4 | 17. 2 | 276 | 600 | 1500 | 300 | 1000 | 10D | 20D |

| 156-192 | 1+4 | 17. 2 | 283 | 600 | 1500 | 300 | 1000 | 10D | 20D |

| 194-216 | 1+4 | 18. 7 | 334 | 600 | 1500 | 300 | 1000 | 10D | 20D |

| 218-288 | 1+4 | 18. 7 | 337 | 600 | 1500 | 300 | 1000 | 10D | 20D |

| 290-432 | 1+4 | 20. 6 | 400 | 600 | 1500 | 300 | 1000 | 10D | 20D |

| 434-576 | 1+4 | 22.8 | 478 | 600 | 1500 | 300 | 1000 | 10D | 20D |

2.The relevant technical Parameters canbe adjusted according to the customer’s demands;

3.The block water way can be adjustedaccording to the customer’s demands;

4.The design flame resistance,anti-rodent, termite resistant cable according to the customer’s demands.

Related products

- Small size, Low cost.

- Up to 24 fibers.

- Uni-tube gel-filled construction for superior fiber protection.

- Two parallel FRP wire and overall glass yarn to enhance tensile resistant.

- And protect cable from mechanical damage.

- Designed for use with inexpensive attachment hardware.

- Self-supported no messenger needed.